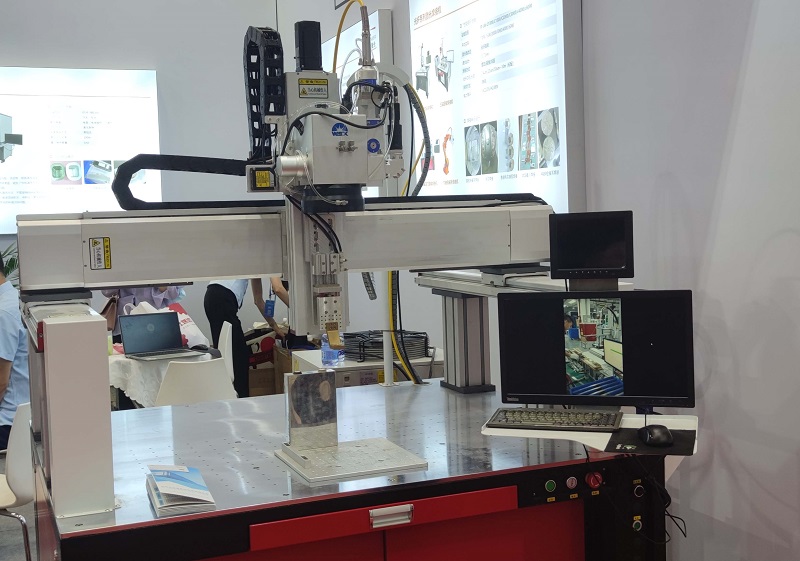

As a critical component of precision machinery, linear modules require proper operation to ensure speed, accuracy, and longevity. Regular maintenance is essential to prevent abnormal wear and maintain optimal performance over the long term. This proactive approach not only extends the lifespan of the linear slide module but also helps in identifying and addressing potential issues promptly. This is especially crucial when the module is not in use for extended periods, requiring careful attention to safety and maintenance practices.

When a linear module is not used for an extended period, inadequate maintenance can lead to decreased accuracy and speed, shortened lifespan, and potential issues like corrosion or rust upon sudden use. Routine maintenance practices include:

1. **Regular Powering On:**

During humid seasons or in environments with high relative humidity, it's important to periodically power on the linear slide module. Even if the machine is locked and the motor isn't running, allowing it to idle helps dissipate moisture within the module using the heat generated by electrical components. This ensures stability and reliability of its performance. Additionally, maintaining a regular power supply ensures the backup battery remains charged. It's crucial to monitor the battery voltage regularly; if it drops too low, replace it immediately to prevent data loss due to power outages.

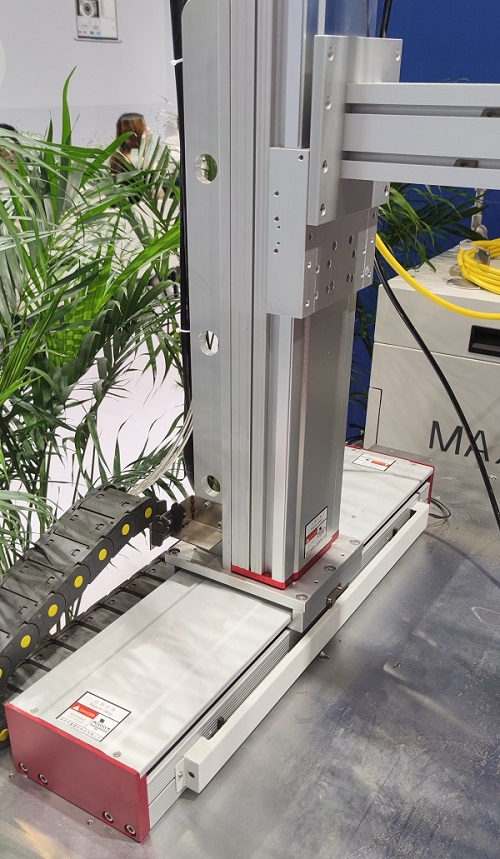

2. **Lubrication Maintenance:**

Regularly apply rust preventive oil and lubricating oil to the linear slide module's ball screws to prevent rust, corrosion, and ensure smooth operation. Clean the surface regularly to remove dust and debris to avoid operational failures.

3. **Enclosure Protection:**

If the module is equipped with a DC motor, when the motor is not in use, remove the brushes from the DC motor and implement enclosed protection measures. This prevents chemical corrosion that could damage the commutator, thereby maintaining the motor's performance and ensuring the linear module operates smoothly.

By adhering to these maintenance practices, you can mitigate potential issues associated with prolonged periods of non-use and ensure the long-term performance and reliability of the linear module.

Precision linear modules have minimal frictional resistance, requiring only small driving forces to move loads. The low-friction materials of linear modules help reduce heating effects, and compared to traditional sliding systems, they exhibit reduced frictional resistance. This characteristic allows them to maintain accuracy over the long term. The summary above represents the insights from the editorial team of Dongguan Ruixiang Intelligent Technology Co., Ltd. regarding maintenance practices for linear modules. We hope this information proves helpful to everyone.