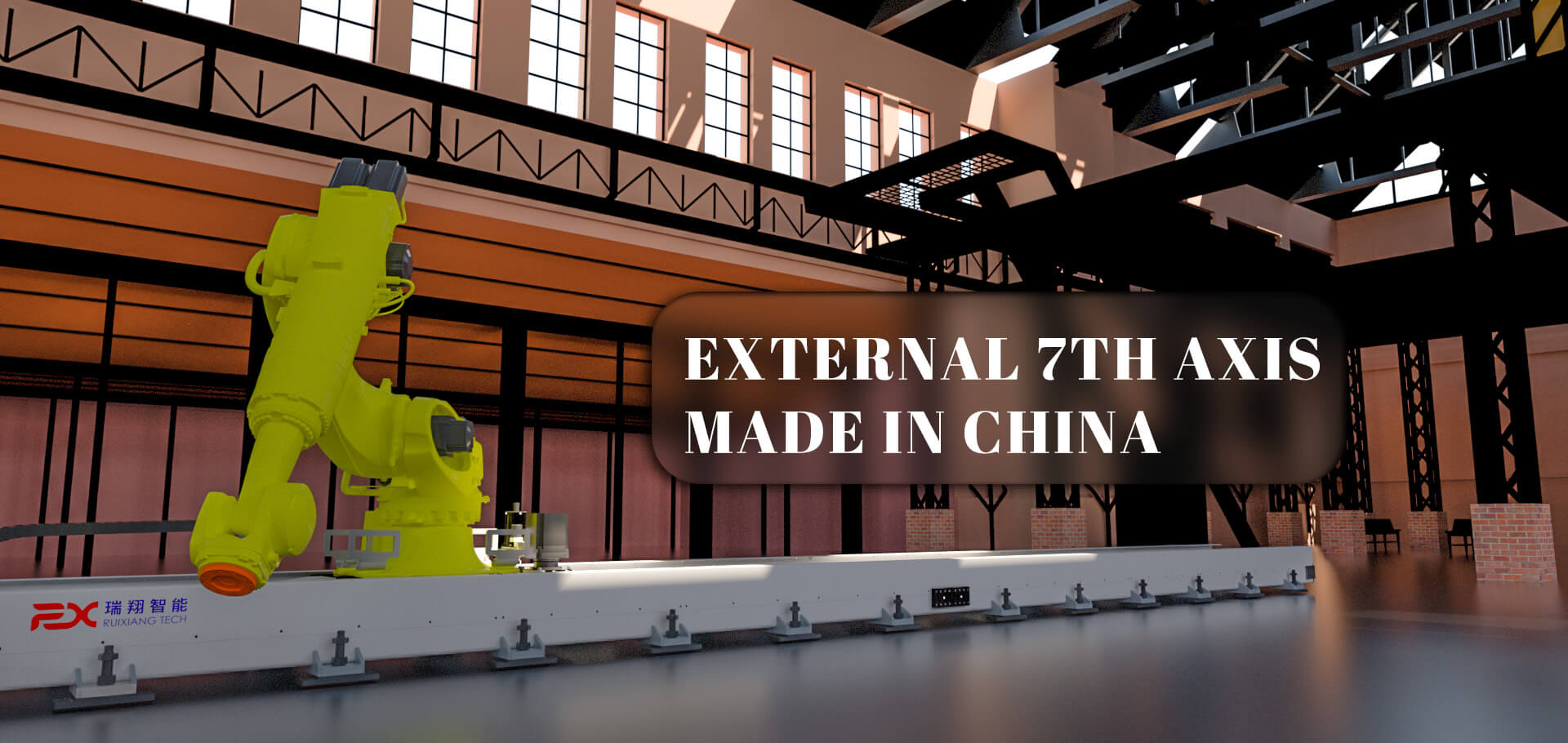

With the development of industrial automation, robots are increasingly used in welding, handling, assembly, and other processes. However, in actual production, many companies find that even six-axis robots still have limitations in their working range. This is where the Robot 7th Axis becomes especially important.

1. What is a Robot 7th Axis?

Th

The Robot 7th Axis is not an independent robot, but an extension of the existing six-axis robot. By adding linear motion capability, it effectively solves problems such as limited working range, large workpiece processing, and production efficiency improvement, helping enterprises achieve higher levels of automation at lower costs.

If you need customized robot 7th axes, linear modules, or gantry manipulators, please contact Dongguan Ruixiang Intelligent Technology Co., Ltd. We provide non-standard automation solutions tailored to your needs.

e

3. Application Examples

Welding production lines: The 7th axis allows robots to complete the entire welding process for large frames.

Loading and unloading: Robots move back and forth on the 7th axis to achieve multi-station loading and unloading.

Painting operations: Robots can spray large products comprehensively, avoiding dead corners.

Robot 7th Axis, also known as an external axis or a robot linear track, is essentially a linear module or rail system. It allows the robot to move linearly in one direction — equivalent to giving a six-axis robot “an extra pair of legs” — thereby greatly extending its working range.

2. What Problems Can the Robot 7th Axis Solve?

(1) Expanding the Working Range

Traditional six-axis robots can only work within a fixed area. With a 7th axis, the robot can move along the track, covering longer production lines or larger workpieces, achieving the effect of one robot replacing multiple robots.

(2) Improving Production Efficiency

With the 7th axis, the robot is no longer limited to a fixed station. It can quickly switch between multiple workstations, reducing redundant investment and increasing the overall utilization of the production line.

(3) Adapting to Large Workpieces

In industries such as automotive, home appliances, and metal structures, workpieces are often very large. Relying solely on a six-axis robot may not cover the entire processing area. By adding a 7th axis, the robot can easily complete welding, painting, or handling of the entire workpiece.

(4) Reducing Enterprise Costs

Without a 7th axis, companies may need to purchase multiple robots to handle different stations. By adding a 7th axis track, one robot can complete the work, saving equipment investment and reducing space usage.

3. Application Examples

Welding production lines: The 7th axis allows robots to complete the entire welding process for large frames.

Loading and unloading: Robots move back and forth on the 7th axis to achieve multi-station loading and unloading.

Painting operations: Robots can spray large products comprehensively, avoiding dead corners.

The Robot 7th Axis is not an independent robot, but an extension of the existing six-axis robot. By adding linear motion capability, it effectively solves problems such as limited working range, large workpiece processing, and production efficiency improvement, helping enterprises achieve higher levels of automation at lower costs.

If you need customized robot 7th axes, linear modules, or gantry manipulators, please contact Dongguan Ruixiang Intelligent Technology Co., Ltd. We provide non-standard automation solutions tailored to your needs.